During PMMI’s recent Virtual Economic Leadership Conference, Consumer Packaged Goods Executives and suppliers met virtually to discuss the economic outlook and trends on the horizon for CPG companies. The conference kicked off with a presentation by Alex Chausovsky, Senior Business Advisor at ITR Economics, discussing current economic conditions and projections that will affect how CPG companies operate into the next decade. As reported by Automation World, a key topic of the presentation was strategic planning around packaging in a world economy with too few warehouse workers and accelerating growth.

“Despite the fact that we have an elevated unemployment rate, skilled workers are going to be very difficult to find and retain,” Chausovsky says. “And so, the less they need to rely upon human labor, the more likely they’re going to be able to prosper in the future, at least from a perspective of outperforming the rest of their peers. So now, in anticipation of that rise is actually a great time to be investing in equipment, because you’re going to need it 6, 9, 12 months down the road, for sure.”

The past year has brought a stark reality check to many CPG companies who saw extreme demand increases for shipped goods and a sharp decrease in available warehouse workers due to the COVD-19 pandemic. Even if the past year can be called an anomaly, companies should not jump to the conclusion that their warehouse staffing problems will cease anytime soon. According to Automation World, there are currently about 450,000 open manufacturing positions that companies are struggling to fill. Combine a worker shortage with increased wages and companies will continue to struggle with packaging products affordably, quickly, and efficiently.

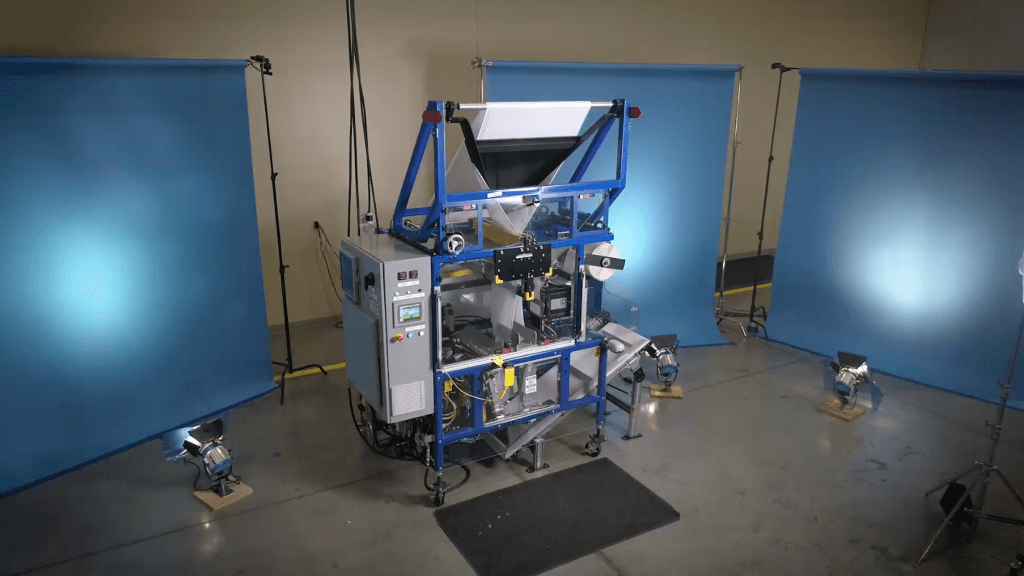

The solution for many forward-thinking companies is automation. A machine like the PACJacket automated packaging system takes raw materials and creates a custom package for each item, sealing it safely inside and sending it on its way. The right-sizing fiber optic sensor chooses the exact right size for the package, reducing material waste and saving money in shipment by eliminating oversized packaging charges. PACJacket increases fulfillment speeds by 400 to 500%, can be operated around the clock and relies on only a single human operator.

“While the social distancing aspect is an imminent benefit, robotic G2P (goods-to-person) systems will provide value long after the pandemic is over,” says Dwight Klappich, VP Analyst at global research firm, Gartner. “This technology is advanced and economical and can easily be tailored to work in every kind of warehouse environment.”