You’ve been asking…and we’re here to answer! Come along with us as we work through some of our most requested questions about cold chain packaging.

What is cold chain packaging?

A cold chain is a series of specialized logistics, packaging, storage, and equipment designed to keep the contents of a shipment within a specific temperature range to prevent spoilage until it reaches its destination. The packaging products used to achieve a cold chain are interchangeably referred to as cold chain packaging, temperature-controlled packaging, and thermal packaging.

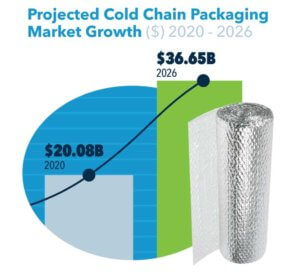

How fast is the need for cold chain packaging growing?

How fast is the need for cold chain packaging growing?

The cold chain packaging market is growing fast, especially within the online grocery and food delivery segments. The cold chain packaging market was valued at $20.08 billion in 2020 and is expected to grow to $36.65 billion by 2026, and its continued growth will be driven by extensive demand for perishable goods worldwide. Revenue from the online food delivery segment is projected to reach $31.91 million in 2021 and is expected to grow at an annual rate of 9.18%, landing at a projected value of $45.33 million by 2025.

The online grocery submarket is also growing fast, with projected growth forecasted to double in the next five years. Most of the U.S. online grocery market share is dominated by two companies, Walmart and Amazon.

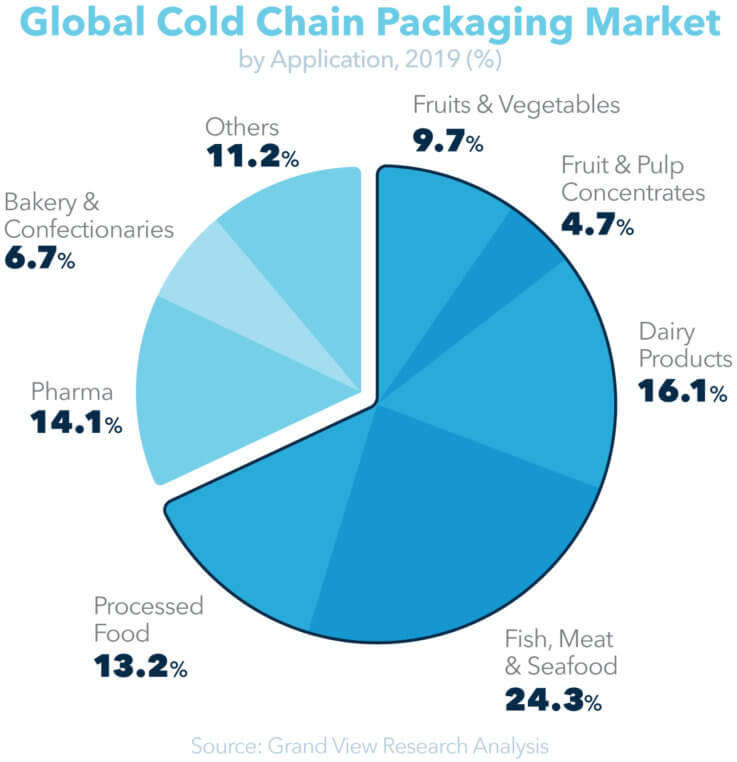

When do I need to use temperature-controlled packaging?

The uses for temperature-controlled packaging are numerous, and most are food-related. As you can see, food products make up nearly 75% of the cold chain packaging market share. The rest of the temperature-controlled packaging market share belongs to pharmaceutical and other industries.

What terms and definitions do I need to know to be able to navigate conversations about temperature-controlled packaging?

Just like many industries, the cold chain industry has its own terminology for temperature-controlled packaging and shipment. Below are definitions for commonly used terms in the cold chain industry!

Temperature control algorithms: A procedure indicating temperatures and times to use as a testing guideline.

Ambient temperature: The temperature of the air surrounding a component.

Chamber (also, environmental chamber): A thermally isolated chamber typically capable of maintaining temperatures within a minimum and maximum by means of a programmable controller.

Cold shock: Cold shock is the rapid decline in product temperature during the initial pack-out phase, when frozen refrigerant comes into contact with the product.

Data logger: An in-transit temperature recorder that measures temperature during a specified time period.

Excursion (also, min/max): An event in which a product is exposed to temperatures outside the range(s) prescribed for storage and/or transport.

Fat bloom: Grayish streaks that appear on the surface and potentially throughout chocolate. This results when chocolate is exposed to warm temperatures, which causes the cocoa butter (aka fat) in the chocolate to soften. When the fat melts, it separates from the other ingredients in the chocolate and rises to the surface, where it then re-solidifies and creates a grayish “bloom.”

Convection: The transfer of heat by air circulation or movement.

Conduction: The direct flow of heat through a material resulting from direct contact.

Radiation: The transfer of heat (infrared radiant energy) from a hot surface to a cold surface across an air space or vacuum.

Isothermal: Involving or possessing a constant temperature.

Pack-out: The steps and procedures necessary to assemble a shipping container with its refrigerants, buffering materials, and product payload.

Payload: Contents of an inner carton.

PCM (phase change material): A material that changes phases from solid to liquid (or liquid to gas) at a single temperature.

Pre-conditioning: Temperature stabilization of a material per requirements (e.g., freezing a gel pack) prior to pack-out.

Refrigerant: Gel packs, foam bricks, wet ice, dry ice, and PCM (Phase Change Materials) intended to regulate temperature within a container.

Sublimation: The process in which dry ice (frozen carbon dioxide) turns into a gas.

Temperatures spike: A rapid increase or decrease in temperature.

Which variables affect temperature-sensitive products while being shipped?

The success or failure of a cold chain shipment starts with the product’s temperature before it leaves the warehouse. This temperature is influenced by many variables, including the product’s temperature when it is packaged and the ambient temperatures in fulfillment areas and shipping areas.

Temperature control variables in a single shipment include:

- Product temperature

- Ambient temperature in fulfillment areas

- Shipment and storage area temperature

- The temperature where the insulation and boxes are stored

How do I ensure that products don’t overheat in shipment? How do I properly package temperature-sensitive products?

One thing is certain—to achieve a cold chain that stays cold, good thermal packaging is highly critical. The temperature within the package must remain within a safe range throughout many temperature changes across the supply chain. When shipping something that is temperature-sensitive, it is important to ask the right questions before you choose a climate-controlled shipping method. These questions include:

- What is the product you are shipping? Size, amount, etc.

- What is your current pack-out? Box, refrigerant, void fill?

- What temperature are your product and insulation? Stored at? Packaged in? Staged in?

- What are your product excursions and duration? Currently as well as desired.

How hot is too hot for your product? How can I learn the safe temperature thresholds for my shipment?

The International Safe Transit Association 7E Heat standard is commonly used to evaluate thermal transport packaging in parcel delivery system shipment. The standard provides heat and cold profiles that allow customers to evaluate the effectiveness of different types of insulated packaging to see how they compare and if they meet the needs of a certain product.

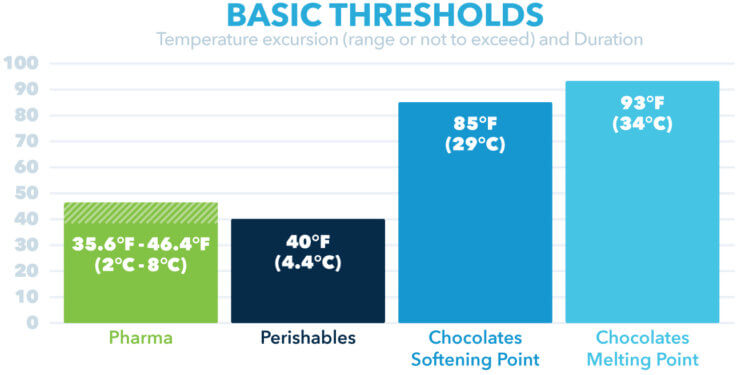

Below are the temperature thresholds for common heat-sensitive products. If you want to keep these items safe from thermal damage during shipment, they need to be kept below these temperatures:

- Pharmaceuticals: 35.6° F to 46.4° F (2° C to 8° C)

- Perishables: 40° F (4.4° C)

- Chocolate softening point: 85° F (29° C)

- Chocolate melting point: 93° F (34° C)

What are the different types of cold chain packaging?

There are many options when it comes to cold chain packaging, and most involve a shell (usually a cardboard box) lined with an insulative material. Ice packs or gel packs may be added to the box for additional cooling.

Types of insulative materials vary in size, shape, and effectiveness; insulative materials for cold chain packaging include cotton/recycled denim, polyurethane, vacuum-insulated panels, EPS (molded panels), polyethylene terephthalate and kraft paper. Many of these types of insulation products are bulky, difficult to store, expensive to ship, and a hassle for customers to dispose of.

How can PAC Worldwide help me navigate temperature-controlled shipping? What is the CoolPAC® product line?

CoolPAC® is our product line made from a unique, reflective bubble material with a high insulation rating and is FDA-approved for food contact. Its low-profile design makes it easy to store and the one-piece box liners increase fulfillment speed. The CoolPAC® material is available in many different forms from box liners, to roll stock-cut sheets, to mailers, and pallet covers.

CoolPAC® is a perfect solution for protecting perishable items in shipments such as:

- Confections and bakery items

- Fruits and vegetables

- Pharmaceuticals

- Processed foods

- Meal kits

- Prepared ready-to-eat food